Choosing IO-Link Master Ports: Type A vs Type B Characteristics and Applications

The application of IO-Link technology in the field of industrial automation is becoming increasingly widespread. With its high flexibility and ease of integration, it has become a key technology for connecting sensors, actuators, and control systems. However, the choice of IO-Link master ports often poses a challenge for engineers, especially in deciding between Type A and Type B master ports. This article delves into the characteristics, application scenarios, and connection methods of these two types of ports to aid in a better understanding and selection of the appropriate IO-Link master.

Physical Connection

Before understanding the Type A and Type B master ports, it's essential to know the basic composition of the IO-Link interface. The IO-Link interface typically uses unshielded three-core or five-core cables, not exceeding 20 meters in length, and features standard four-pin or five-pin connectors. The master ports are divided into Type A and Type B, each suitable for different application scenarios.

Type A Ports

Type A ports generally use a 4-pin M12 connector, where the functions of pins 2 and 5 are not specified. Manufacturers define these functions. Pin 2 is usually assigned an additional digital channel.

Type B Ports

In contrast to Type A, Type B ports use a 5-pin M12 connector, capable of providing additional power voltage, and are suitable for connecting devices with increased power demands. In this case, pins 2 and 5 are used to provide additional (electrically isolated) power voltage.

Differences in Pin Definitions

From the pin definitions, we can conclude that in the IO-Link system, the main difference between Type A and Type B ports lies in the pin configuration of the cable, especially the use of pin 2 and pin 5. These differences significantly impact their functionalities and application scenarios.

Type A ports are widely used for connecting standard sensors and actuators, suitable for most industrial automation applications. Meanwhile, Type B ports can provide additional load power, suitable for devices with higher current or voltage requirements, such as valve islands.

Connecting Master and Slave Stations

Having understood the physical connections and pin definitions of Type A and Type B ports, let's look at how these ports are correctly connected to the slave stations. In the "IO-Link Design Guide", the following three main connection methods are introduced:

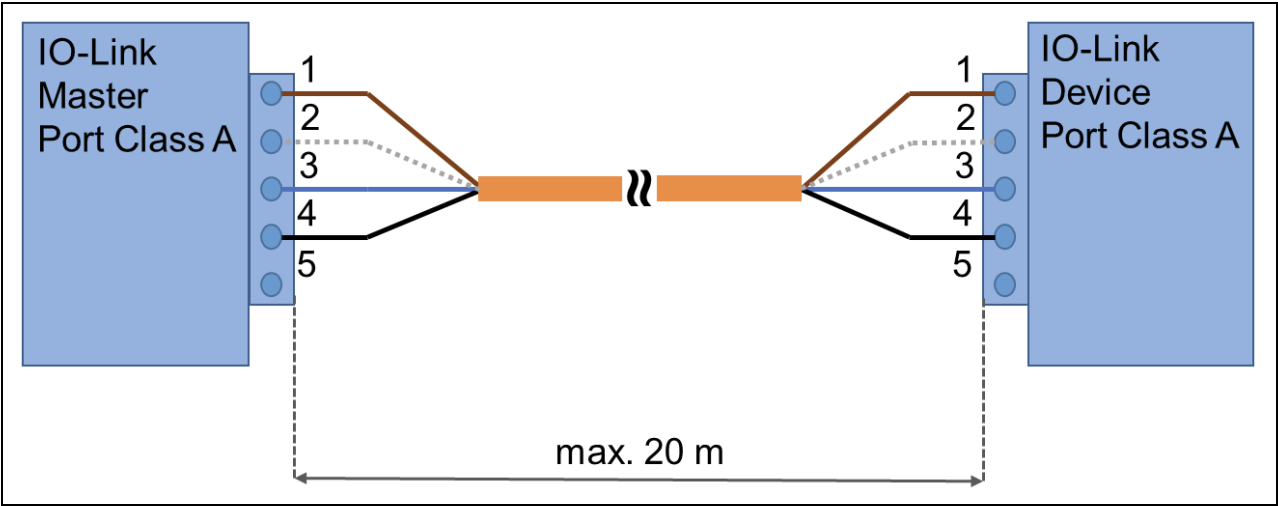

Type A Master with Type A Slave

This is the most common connection method, usually using three-core unshielded control lines. If four-core or five-core cables are used, pins 2 and 5 on the device end should be left empty or ensure that the additional voltage does not cause failure of the IO-Link device.

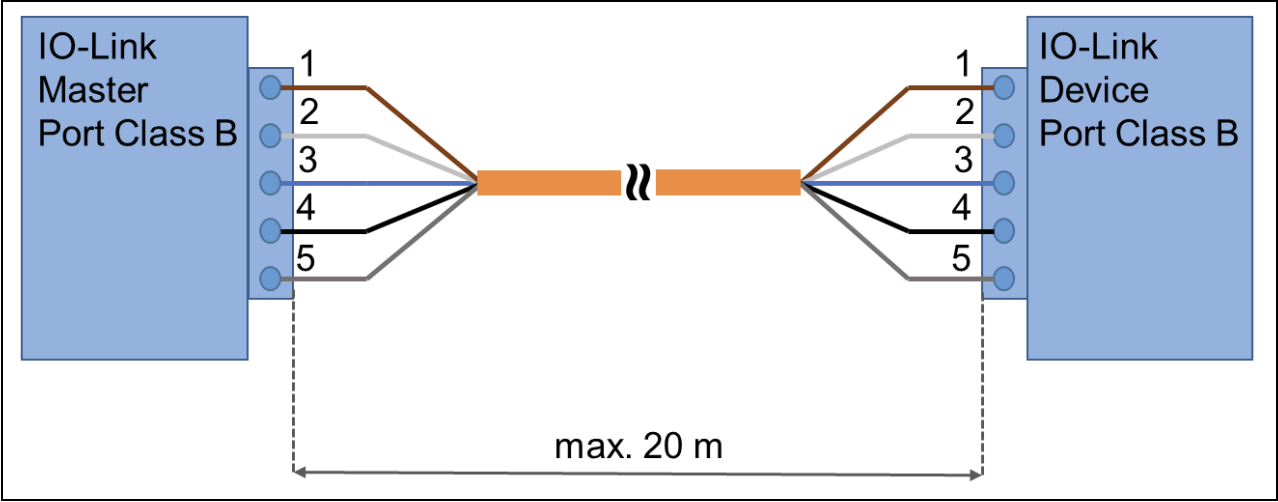

Type B Master with Type B Slave

This connection method is suitable for Type B port IO-Link master stations and Type B port IO-Link devices. In this configuration, the cable's cores are connected to the respective individual terminals, especially suitable for devices or master stations of IP20 grade. For IP67 grade devices, the connector's definition is as shown in figure 1.

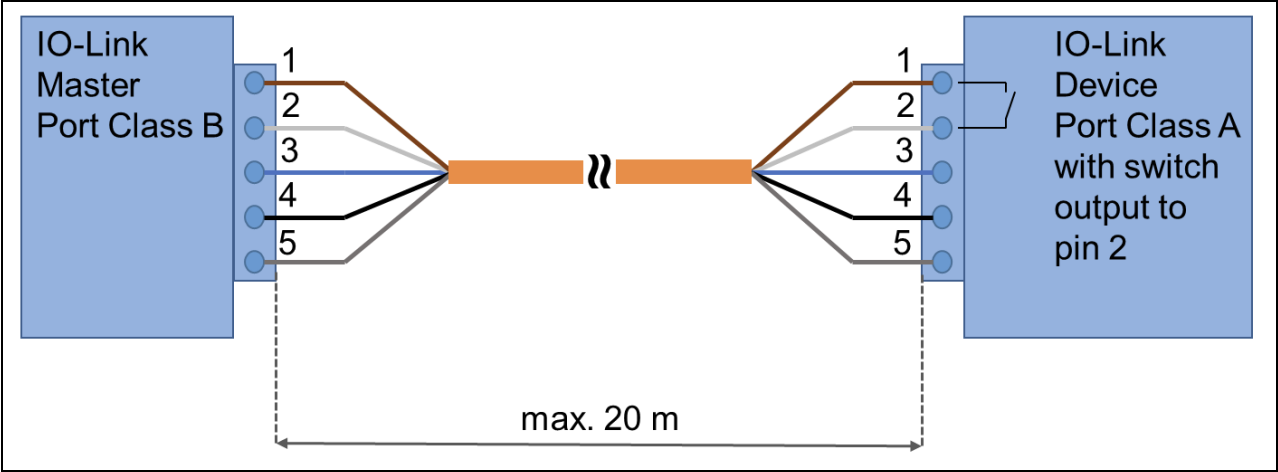

Type B Master with Type A Slave

This is a special connection method used to connect a Type B port IO-Link master station with a Type A port IO-Link device. In this case, using a five-core cable for connection is not recommended, as it may disable any configured emergency stop function.

Conclusion

Type A and Type B IO-Link master ports each have their unique advantages and application scenarios. Type A ports are suitable for most standard industrial automation applications, while Type B ports are more appropriate for complex devices with higher current or voltage demands. Understanding the physical connections, pin definitions, and different connection methods of these two types of ports is crucial in designing and configuring IO-Link systems. The correct choice of ports and connection methods will ensure the safety and efficiency of the system.

For more information on IO-Link master and slave products, please contact our sales personnel or call the company. We have a professional technical team ready to provide customized customer support and efficient after-sales service, ensuring the maximum protection of every user's interests.