SENTINEL IO-Link products: Enhancing stability and usability in industrial automation

IO-Link is a communication protocol specially developed for sensors and actuators, bringing an end to the history of no communication between controllers, sensors, and actuators. This protocol enables the controller to have real-time control over the lowest-level process data and operational status information. In the past 10 years, in the field of industrial automation, the application of communication technology between sensors, actuators, and controllers has become increasingly widespread.

SENTINEL IO-Link products have emerged in response to the times. During the use of IO-Link products, I have felt their power and had a very satisfactory experience.

In 2021, on the automated production line of the raw material warehouse at the BYD New Energy Battery Manufacturing Base in Yancheng, Jiangsu Province, as the project implementers, we have made extensive use of Tianjin SENTINEL IO-Link communication products at the site execution layer of the raw material warehouse's inbound and outbound conveyor lines, based on the actual requirements of the project. This enables direct data communication between the field sensors and the PLC, and also allows diagnostic information to be sent to each sensor channel. In terms of effectiveness, this solution has fully met the requirements. The project has been running steadily for over a year, and the failure rate of SENTINEL IO-Link products is 0, which has received unanimous praise from users, integrators, and development and debugging personnel for its high reliability and ease of use.

High Stability Design

First of all, the design of SENTINEL IO-Link products takes into account the high stability of the system. During our usage, we have found that the addition of its IP67 protection rating ensures that even in complex and challenging environments in the factory, the system has never experienced power outages, malfunctions, data loss, or any other failures. Therefore, we do not need to maintain or handle it. The four sets of IO-Link subsystems used in this project have all been running flawlessly for over a year, proving the stability of the products through practical tests.

Prominent embodiment of usability

Secondly, SENTINEL IO-Link products also excellent in usability. During project debugging, if common installation problems such as configuration errors or connection failures occur, the on-site debugging engineer can easily quickly locate the problem through the several indicator lights integrated on the IO-Link panel, improving debugging efficiency; When debugging is completed and put into use, the status indicator lights of the IO-Link can help the debugging engineer easily and quickly understand the operating status of the module. By judging the sensor signal status quickly and accurately based on the color changes of the indicator lights on each channel, device faults can be quickly identified.

Seamless integration with PLC master control system

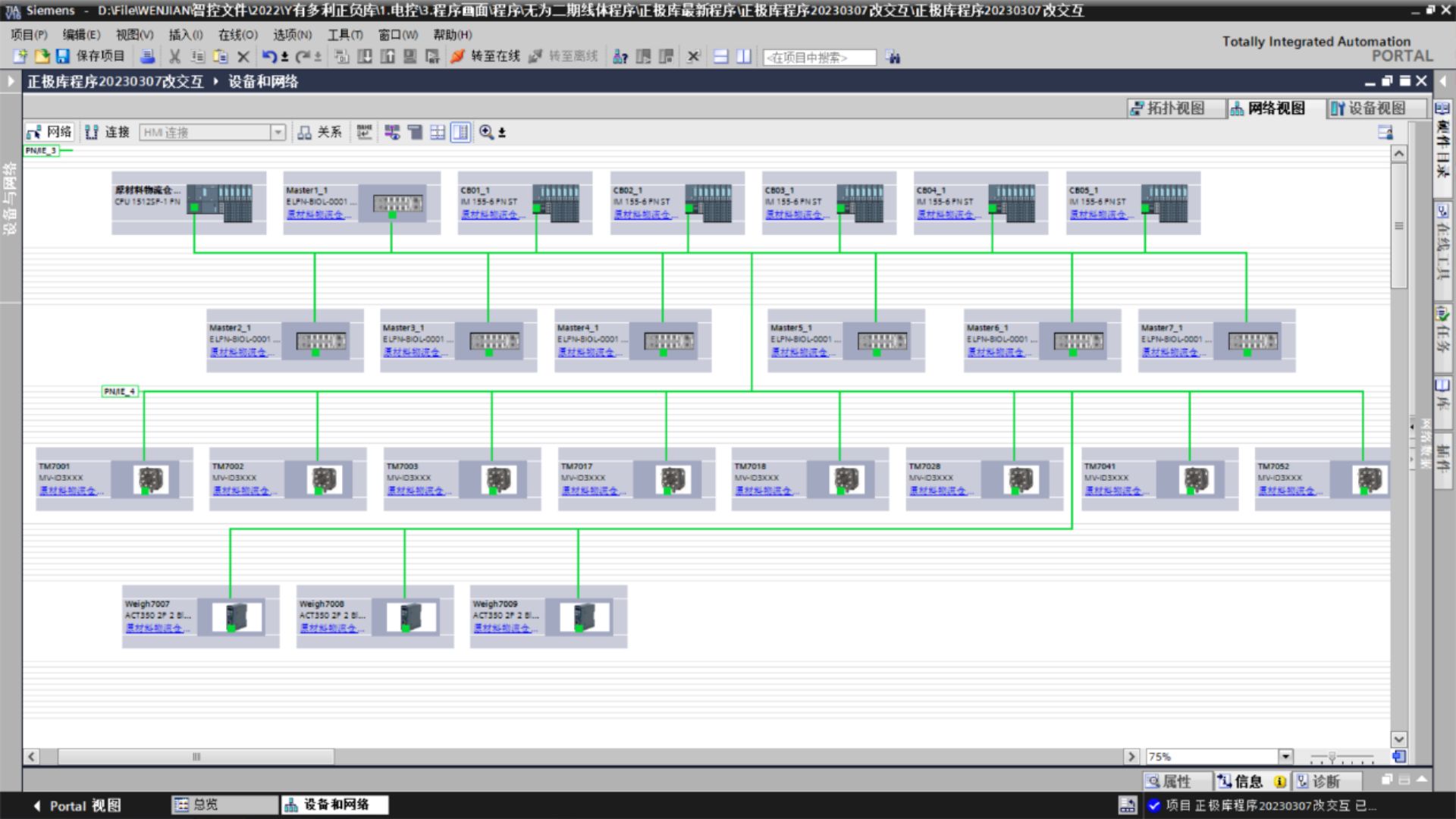

The ease of use of SENTINEL's IO-Link products is also reflected in the integration with the PLC main control system: in this project, the main control PLC adopts S7-1500 from SIEMENS Company, and the control network adopts Profinet industrial Ethernet. The project is in the construction process , using the GSD file of the module, our PLC development engineers completed the system configuration as quickly as using SIEMENS’s own distributed IO modules.

When configuring the device, its features such as simple configuration, convenient operation, and excellent expansion capability all made me sigh at the design intentions of SENTINEL's IO-Link products—it has well inherited the SIEMENS Botu PLC design platform. Convenience and error-proof design effectively inherit the consistency of hardware configuration operations and improve configuration efficiency.

Conclusion

Overall, in this project, we unanimously believe that the use experience of SENTINEL IO-Link is excellent. Compared to the traditional IP20 cabinet-mounted distributed I/O modules, SENTINEL IO-Link system excels in environmental adaptability, scalability, ease of debugging and construction, as well as comprehensive cost-effectiveness. It is outstanding in both user experience and safety performance, effectively improving equipment operation efficiency and stability, and promoting the development of smart manufacturing. It provides us with a reliable, efficient, safe, and cost-effective automation solution.