FAQ|How to choose a pressure sensor

In various industries, pressure is a very important physical quantity that needs to be monitored and responded to in real-time. Pressure sensors are ubiquitous in their application. These devices detect changes in the pressure of liquids or gases and convert this information into usable output signals, becoming an indispensable part of modern industry. So, how should you choose a suitable pressure sensor based on your own needs?

Types of Sensors and Working Principles

There are several types of pressure sensors, including piezoresistive, capacitive, piezoelectric, and fiber optic sensors:

- Piezoresistive Sensors - Work based on the piezoresistive effect, that is, when a material (usually a semiconductor or metal) is subjected to pressure, its resistance changes, and this resistance change is converted into a voltage or current change, thus producing an electrical signal proportional to the applied pressure. Because of their high precision and stability, they are commonly used to monitor and control industrial process pressures.

- Capacitive Sensors - Capacitive sensors use changes in capacitance to measure pressure. They typically contain two metal plates, one of which is movable. When pressure is applied to the movable plate, the distance between the two plates changes, causing a change in capacitance. This change in capacitance is then converted into an electrical signal. Due to their high sensitivity and small size, they are suitable for applications requiring miniaturized sensors, such as medical devices (blood pressure monitoring) and miniature robots.

- Piezoelectric Sensors - Work based on the piezoelectric effect, that is, certain materials (such as quartz, some ceramics) generate a charge when subjected to mechanical pressure. When pressure is applied to these materials, the generated charge is proportional to the applied force. These charges can be measured and converted into electrical signals, thus obtaining the pressure value. Piezoelectric sensors are particularly suitable for measuring dynamic or rapidly changing pressures, such as explosion testing and automotive crash testing.

Overload Pressure and Range

When choosing the right pressure sensor, there are several key factors to consider:

- Overload Pressure - It refers to the maximum pressure that the pressure sensor can withstand. The maximum pressure of the entire system should not exceed this pressure to avoid sensor overload damage.

- Range - The detection range of the pressure sensor. The commonly recommended practice is to choose a range so that the normal working pressure of the system is about 50% to 75% of the sensor range. This allows for enough room to cope with unexpected pressure increases without sacrificing too much accuracy. When choosing a range, the required accuracy should also be considered. A smaller range usually provides higher accuracy. If the application requires high accuracy, a relatively lower range may need to be selected.

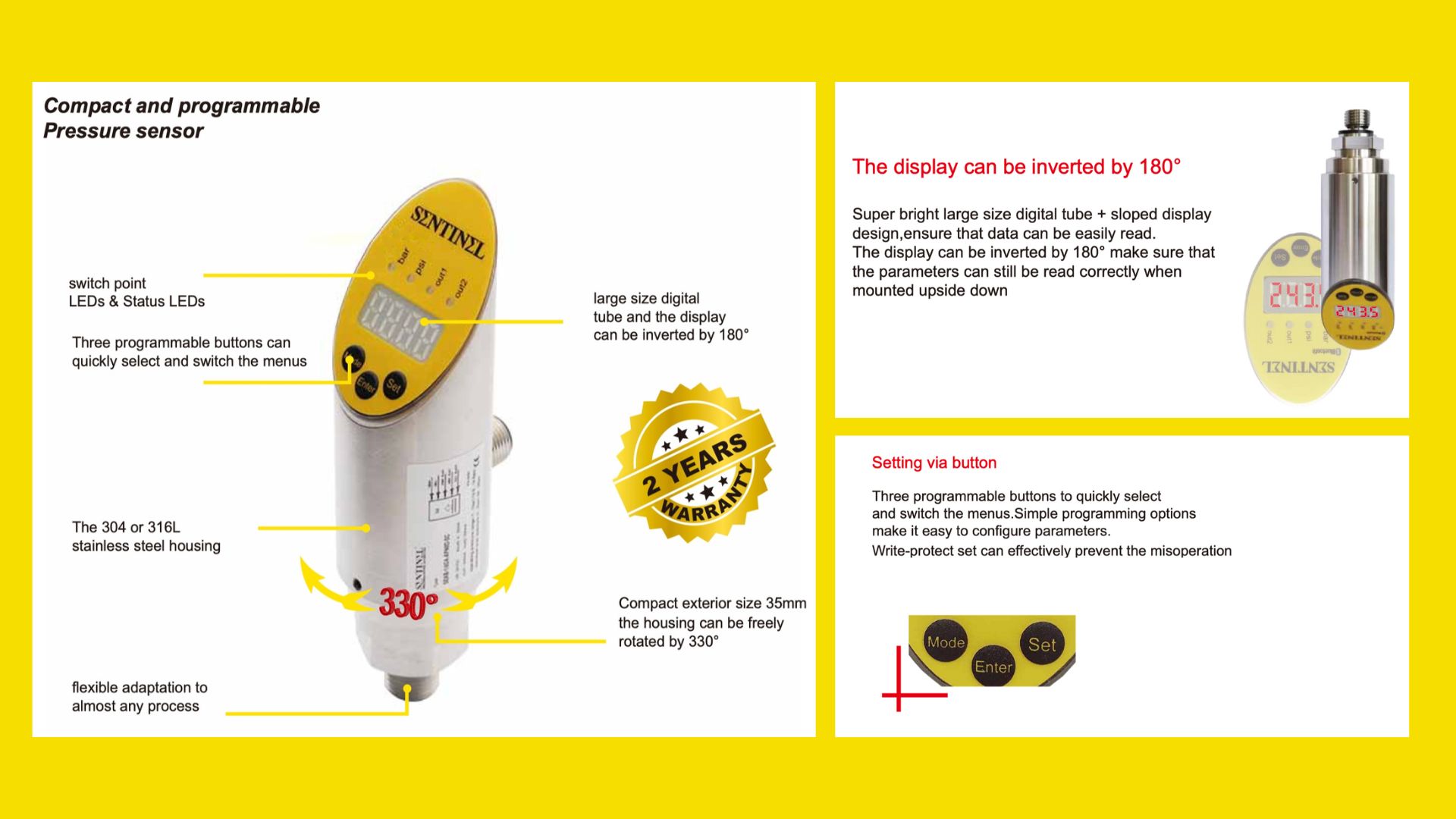

SENTINEL's Pressure Sensors

Our company's (piezoresistive) pressure sensors are designed to adapt to harsh industrial environments, with their sturdy stainless steel casing ensuring long-term durability and reliability. The unique design allows the body to rotate up to 330 degrees, greatly simplifying the installation process and easily adapting to any industrial setting. Additionally, our sensors are equipped with a 4-digit 7-segment digital display, supporting mirror flip function, making data reading more convenient and intuitive. No matter the installation angle, you can easily read the measurement data. To enhance user experience, we have also equipped the sensors with three programming buttons, which are simple and intuitive to operate, ensuring easy control and rapid response even in complex industrial environments.

Conclusion

When choosing a pressure sensor that suits your needs, it is crucial to understand the working principles and characteristics of different types of sensors. The right choice can ensure the efficient and safe operation of the system.

In this rapidly developing era, we firmly believe that through continuous technological innovation and a deep understanding of customer needs, we can provide you with the highest quality products and services, helping your business grow. We look forward to working with you to create a better future.