SENSORS

SENSORS

Pressure is one of the most frequently measured parameters in industry, whether it is a press, a cooling circuit or a storage tank, there is a need to monitor and measure pressure parameters. SENTINEL’s compact pressure sensors and pressure transmitters have: a variety of different connection sizes and output signals, as well as a wide pressure range, rich function settings and flexible installation methods, which can meet the various needs of actual production. Your design offers the greatest flexibility.

PRODUCTS PARAMETERS

SENTINEL's pressure sensors and transmitters are devices designed to measure the pressure of gases or liquids. They are widely applied in industrial automation, food and beverage processing, metallurgy, machine tools, Hydraulic System, and other fields. Their core functions include pressure monitoring and control to ensure process safety, enhance production efficiency, and optimize product quality.

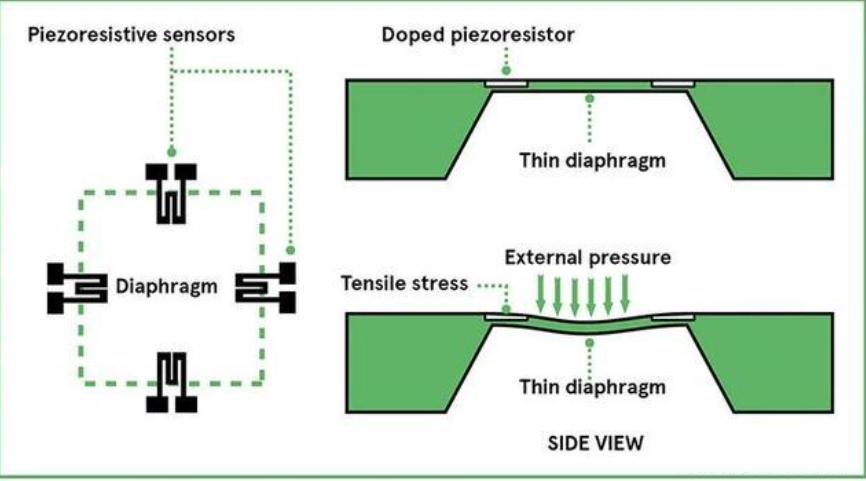

FeaturesThe piezoresistive pressure sensor operates based on the piezoresistive effect—where the electrical resistance of semiconductor or metallic materials changes under pressure. This resistance change is converted into a voltage or current signal proportional to the applied pressure. The sensor typically contains a measuring diaphragm with one side exposed to the measured medium and the other to a reference pressure (such as atmospheric pressure or vacuum). The diaphragm deforms due to pressure differential, and the degree of deformation reflects the pressure difference, enabling accurate pressure measurement.

SENTINEL pressure sensors and transmitters, developed by Tianjin SENTINEL Electronics Co., Ltd., are widely deployed across multiple industrial sectors including powder metallurgy, beer brewing, and vacuum coating equipment.

Additionally, SENTINEL sensors demonstrate high precision, stability, and intelligence in other demanding applications such as photovoltaic monocrystalline silicon production lines, hydraulic systems in the pharmaceutical industry, and industrial cooling circuits—making them ideal for rigorous measurement requirements in challenging industrial settings.