Post-holiday Training for SENTINEL Production Team

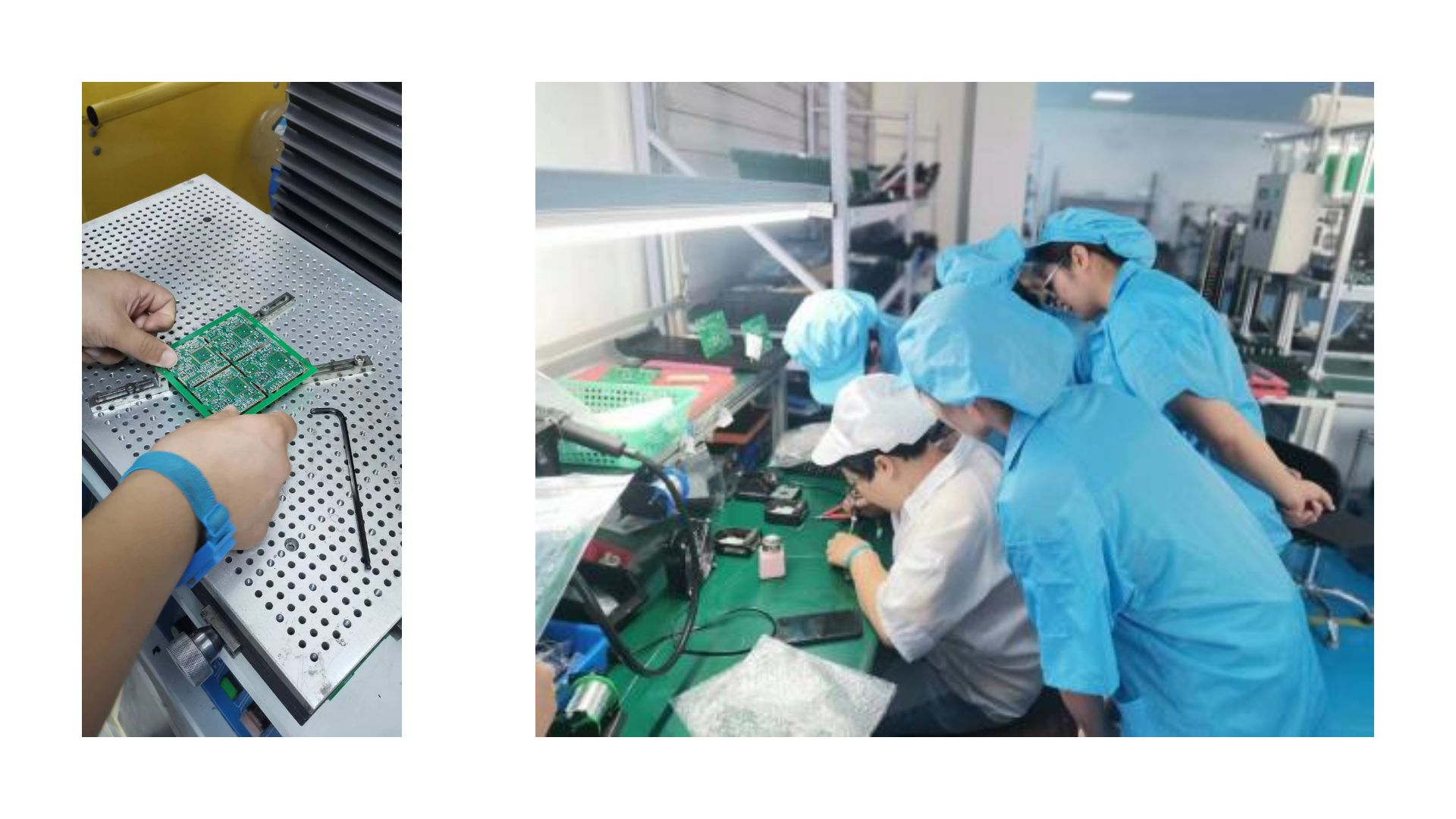

The short eleven-day vacation has already passed, and every employee of the company has returned to their positions with a good spirit. In order to improve the quality and production efficiency of SENTINEL products, the requirements for standardized production and PCB soldering skills are increasingly high. Therefore, the company immediately arranged some key production personnel for PCB soldering training after the holiday. The following is the content of this training:

Welding process

First of all, a series of learning and exploration has been conducted on the control of the key process of PCB soldering. In terms of the soldering process, the employees have a detailed understanding of various aspects, ranging from the selection of solder materials, control of solder joint temperature, to precise calculation of soldering time. The process engineer explained in detail the significant impact of different materials and their ratios on solder joint quality, and also shared practical techniques on how to maintain the stability of solder under high temperatures and prevent cold soldering. During the on-site soldering operations, everyone observed that under regulated procedures, the solder joints were uniform, compact, and aesthetically pleasing. They also attempted hands-on soldering operations under guidance to experience the connection between theory and practice.

Testing Process

In terms of inspection, before mounting, the employees will first conduct first article inspection, checking the capacitance and resistance of each position on the circuit board to see if the specifications are accurate. If they are correct, the mounting process will proceed. Every step from removing the tin, to mounting, to soldering has inspection procedures and standards. If the machine reports an error, the step where the problem occurred will be checked. Before replacing materials, it is necessary to inspect whether the material specifications are consistent. If they are the same, the materials will be replaced.

PCB Solder Paste Printing

Thirdly, employees also learned the skills and methods of PCB solder paste printing and soldering fine-pitch integrated circuits. Solder paste printing is a very important step in SMT (Surface Mount Technology), mainly used to add solder paste to PCB (Printed Circuit Board), and plays a crucial role in manufacturing circuit connectors. They learned and mastered how to secure PCB and the use of scrapers. In terms of soldering fine-pitch integrated circuits, they learned how to accurately control the amount of solder, avoid bridging phenomena, and the techniques for treating fine-pitch and efficient soldering in high-density circuits. During the practical training, under the guidance of professionals, they participated in practical exercises and mastered some common problems and solutions encountered in actual applications.

Learning is just a part of mastering skills. After training, the employees self-organized additional exercises specifically targeting the learning content in order to consolidate and enhance their professional skills in welding and inspection through practice.

Through the training in PCB soldering, we have realized that the company needs to continue improving. There is a great need for enhancing necessary quality control measures, the professional skills of operators, as well as the mental awareness and capabilities of employees. There is still much more for us to do. For example, improving inspection methods (mechanization replacing manual labor), strengthening first article inspection, self-inspection, and patrol inspection gradually.

We believe that there is unlimited potential for improvement as long as we constantly strive for better products and employees.